Height measurement program can be deployed directly into the SoC of LiDAR, saving hardware costs.

Richbeam's volume scanning module solves the problem of density variation of mash during brewery operation. The module uses the principle of 3D scanning with a volume accuracy of up to ±2%. By measuring the volume density in the mash tank in real time, it replaces manual compensation and achieves full tank verification without temperature/humidity interference.

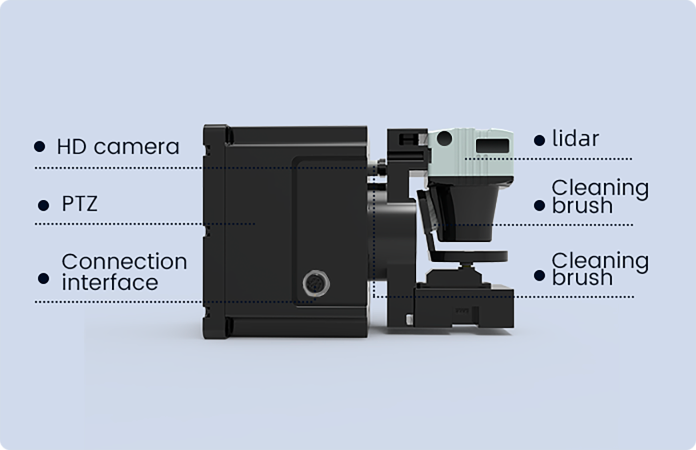

Richbeam's volumetric measurement module integrates LakiBeam LiDAR (270° FOV), PTZ mechanism (360° pan), and HD camera for automated 3D point cloud reconstruction. The system captures bulk material topography at 0.5° angular resolution, processing data via Ethernet/IP protocol to central monitoring systems.

The BeamMaster1 provides volumetric scanning of brewery bulk materials at a range of 40 meters, operating at a scanning frequency of 30Hz to ensure complete coverage.

LiDAR Selection

The BeamMaster1 provides volumetric scanning of brewery bulk materials at a range of 40 meters, operating at a scanning frequency of 30Hz to ensure complete coverage.

Equipment Assembly

Solution Advantages

IP67 Ingress Protection, waterprrof and dustproof, adaptable to complex outdoor environment.

With edge gateway, equipment can realize remote monitor, real-time alarm, information upload and other functions which need remote control.

The retort pot equipment does not need to be moved, when the PTZ is rotating in the vertical direction, the size of the volume can be obtained.

Recommended Scenarios

Customization

Didn't find a LiDAR that meets your requirements? Let's discuss your problem together. Our professional technical team can provide you with customized services.

Contact Our Experts