Centimeter-level accuracy ensures reliable volume calculations, minimizing errors from manual methods.

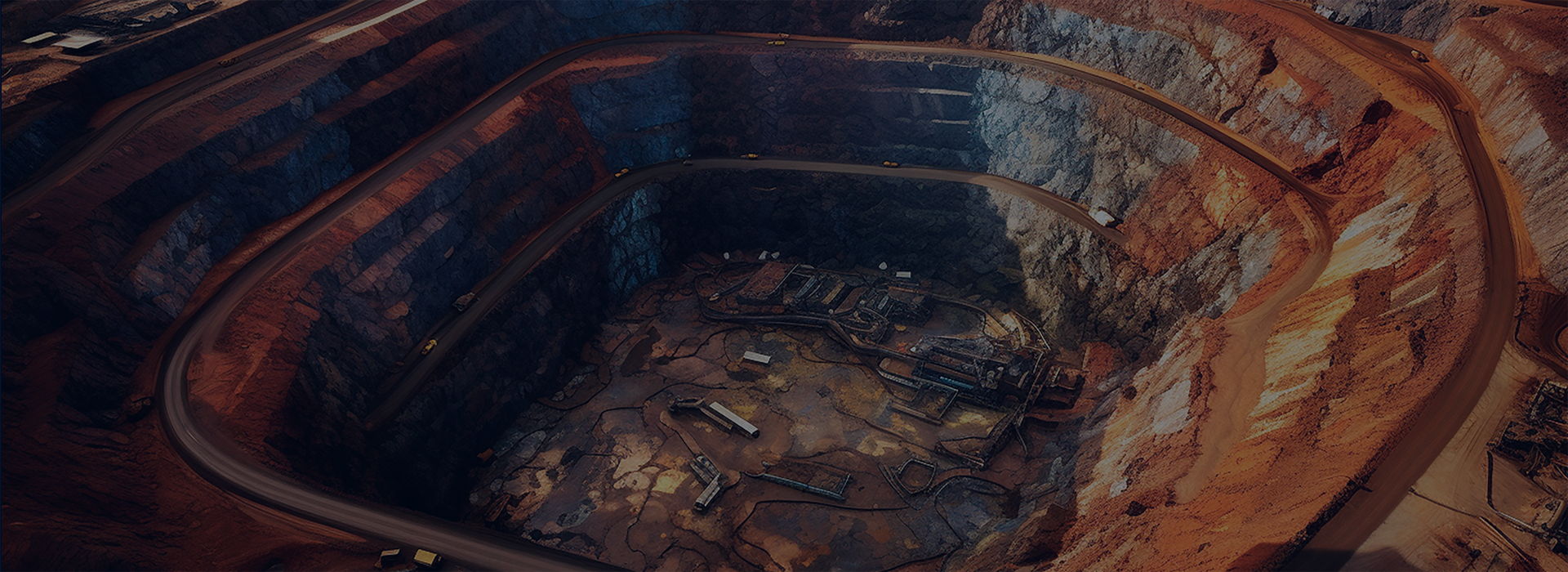

Accurate stockpile volume measurement is crucial in mining management. Traditional measurement methods (total stations, GPS, manual measurements) are slow, labor-intensive, and error-prone due to human error and complex terrain. Therefore, To improve measurement efficiency and accuracy, LiDAR technology offers a faster and more precise solution.

Install LiDAR sensor at the base of the conveyor belt for 270° high-visibility scanning. The collected point cloud data is processed via software for cleaning and filtering, ultimately calculating the precise volume of the stockpile.

Richbeam's 3D Lidar scanning module features high precision, high performance, and a wide scanning range, with a detection distance of 0-50m. It can complete large-area scans in a short time. Additionally, Richbeam provides visualization software for parameter adjustment and data export.

LiDAR Selection

Richbeam's 3D Lidar scanning module features high precision, high performance, and a wide scanning range, with a detection distance of 0-50m. It can complete large-area scans in a short time. Additionally, Richbeam provides visualization software for parameter adjustment and data export.

Equipment Assembly

Solution Advantages

Enables rapid large-area scanning and volume calculation, significantly reducing measurement cycles and saving labor and time costs.

Built-in brushes remove dust and debris, maintaining consistent performance in harsh environments.

Leverages the LiDAR’s onboard SoC to run volume algorithms directly, eliminating additional hardware and saving costs.

Recommended Scenarios

Customization

Didn't find a LiDAR that meets your requirements? Let's discuss your problem together. Our professional technical team can provide you with customized services.

Contact Our Experts